Planung

Planning is everything. Or: without planning everything is nothing! Quality assurance begins with planning. After the inquiry by our customer, the tasks are divided among our qualified staff and the inquiry regarding the steel is sent to our in-house warehouse.

At the same time, the resources of our own production and the capacities of the carefully selected 1,500 suppliers are requested. This creates a stable, binding framework from the outset within which the order can be processed.

Abwicklung

Close cooperation with our suppliers and our own production facilities has created a well-coordinated process in which qualified Stahlberg employees coordinate and monitor scheduling and planning specifications with the aid of modern EDP.

Every process in the production chain can thus be planned and controlled.

The result is a transparent production process that is completely controlled and quality-assured by Stahlberg.

One factor that should not be underestimated is the organisation of logistics. Especially the coordination of delivery routes can be a decisive factor for adherence to delivery dates and project success in complex multipart orders. Here Stahlberg is able to convince through the handling of its own fleet of vehicles.

Kontrolle

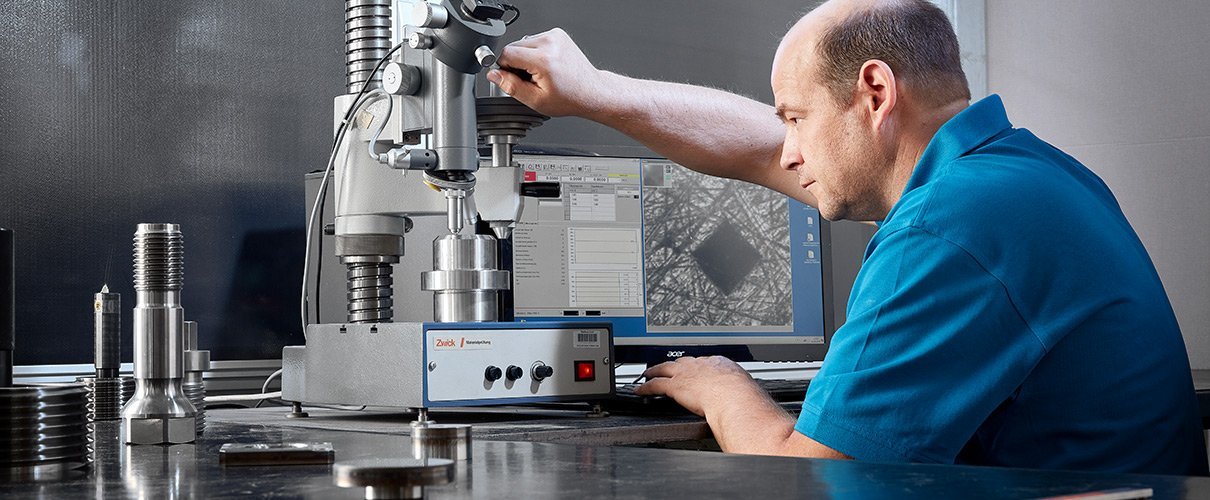

The manufactured products are controlled by our own quality department to guarantee our high standards. Quality assurance at Stahlberg has a wide range of calibrated measuring equipment at its disposal.

Trained employees use both OES (optical emission spectrometer) and XRF (X-ray fluorescence spectrometer) for material analysis and identification. The hardness of the material can be determined with different measuring methods.

Approximately 700 hand-held measuring devices and 2 Faro-Gage measuring arms are used to measure the geometry. Furthermore the surface roughness can be measured. Surface crack testing is carried out by certified Stahlberg personnel using the dye penetrant method.

Further destructive and non-destructive tests can be carried out by accredited test laboratories with whom Stahlberg works closely.

If the goods are accompanied by a certificate, this document is tested on the basis of the order conditions and the current standards. Only after all tests have been passed will the goods be released for sale.

Surface crack testing is carried out by certified Stahlberg personnel using the dye penetrant method.

Further destructive and non-destructive tests can be carried out by accredited testing laboratories with whom Stahlberg works closely.

If the goods are accompanied by a certificate, this document is tested on the basis of the order conditions and the current standards. Only after all tests have been passed will the goods be released for sale.

Quality assurance process at Stahlberg

Archivierung

The complete traceability of the product is guaranteed by the archiving methodology of Stahlberg. This gives all parties involved security in the correct handling of the production processes.

Due to our experience with a wide range of orders, every step in the process is documented by our sophisticated EDP system. This also simplifies the repetition of complex tasks and saves time.

For the continuous optimization of processes, products and services, the employees are trained and further qualified according to a defined training plan. It goes without saying that Stahlberg is aware of and takes into account standards and quality classes.